WOBOT SAFETY

Our team practices safety from start to finish. From the idea board to the field competition. During the design process our team considers several things to keep our team safe. To start off we use belts and pulleys instead of chains and sprockets. Belts insure that if someone or something were to get in caught in the belt it would do less damage than the shearing action of the chain and sprocket. We also use a contained drive system which protects both the bot and us.

We use structural components to contain the drive system which effectively renders them as guards. We have added guards where appropriate. The guards also serve as space to display our sponsors logos. We use bumpers as required by FIRST to protect the robot and to display our team number. In our design we tried to eliminate as many pinch points as possible.

We remove stored energy from the robot when it is shut down. The stored air is relieved by the dump valve. All air powered actuators are designed to default to their current position when air pressure is relieved. This is accomplished by using detent valves. Electrical energy is removed by opening the main breaker and physically disconnecting the battery with the plug. Our team makes sure the battery is securely fastened by building a cradle with straps for extra strength.

In the pit we use our canopy frame to hold power and data cables in the form of drop cables. This keeps them off the floor and becoming a tripping hazard for the team or tangle hazard for the robot. It also keeps the cables from being damaged.

- All people with hair longer than shoulder length, MUST tie back their hair while working on any robot component

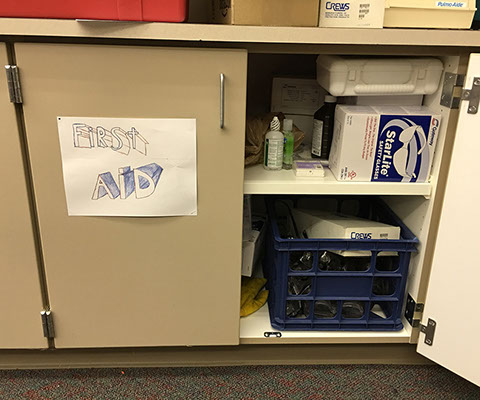

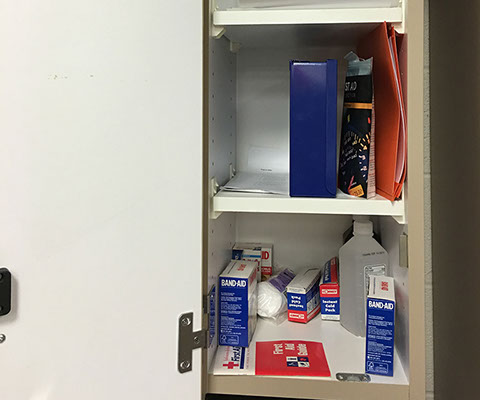

- All Bot Cave meeting rooms contain a clearly marked FIRST AID area

- Design + Build team all has to take (and pass!) a Safety test before using any machinery

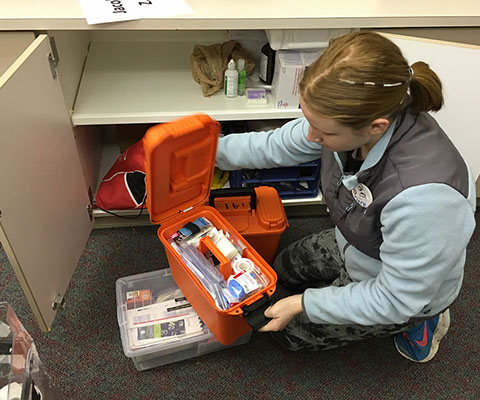

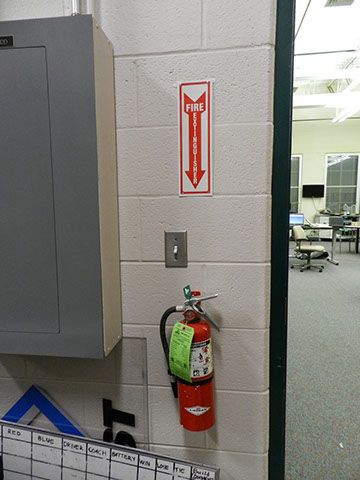

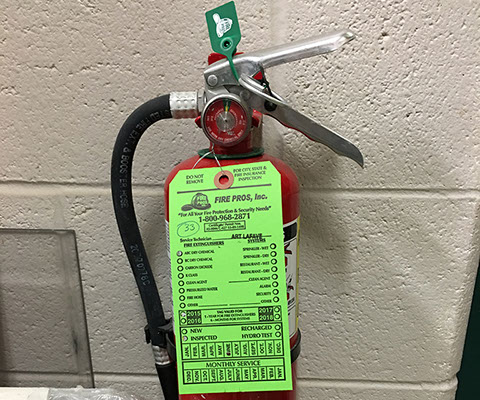

Check out our non-travel safety item checklist! These are items we make sure to have on-hand around the Bot Cave, for emergencies and general safety.

Previous

Next